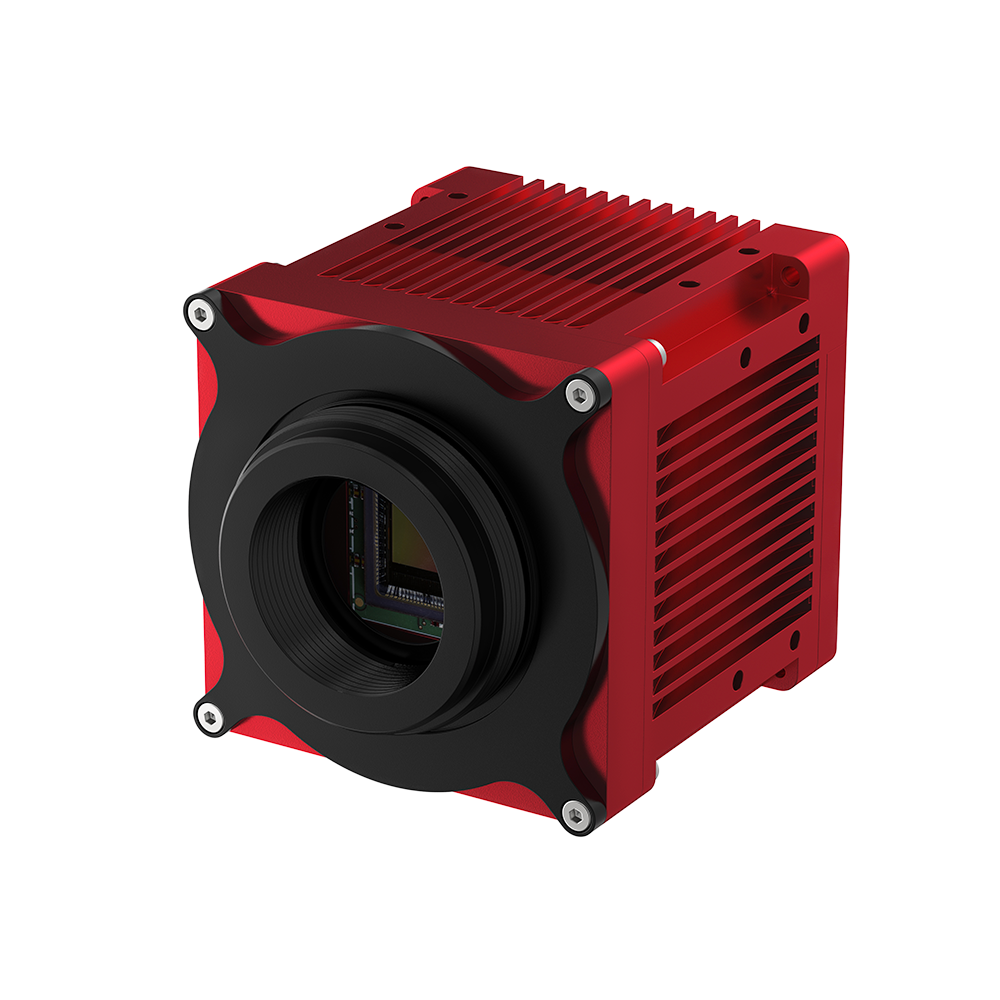

High-Resolution 3D Camera with 1G ethernet interface

- Integrated 3D Sensor C6 Series

- Four different sensor resolutions available (1280, 2040, 3070, 4090)

- Profile speed of up to 200 kHz and up to 614 million 3D points per second

- Available with 1G Ethernet interface

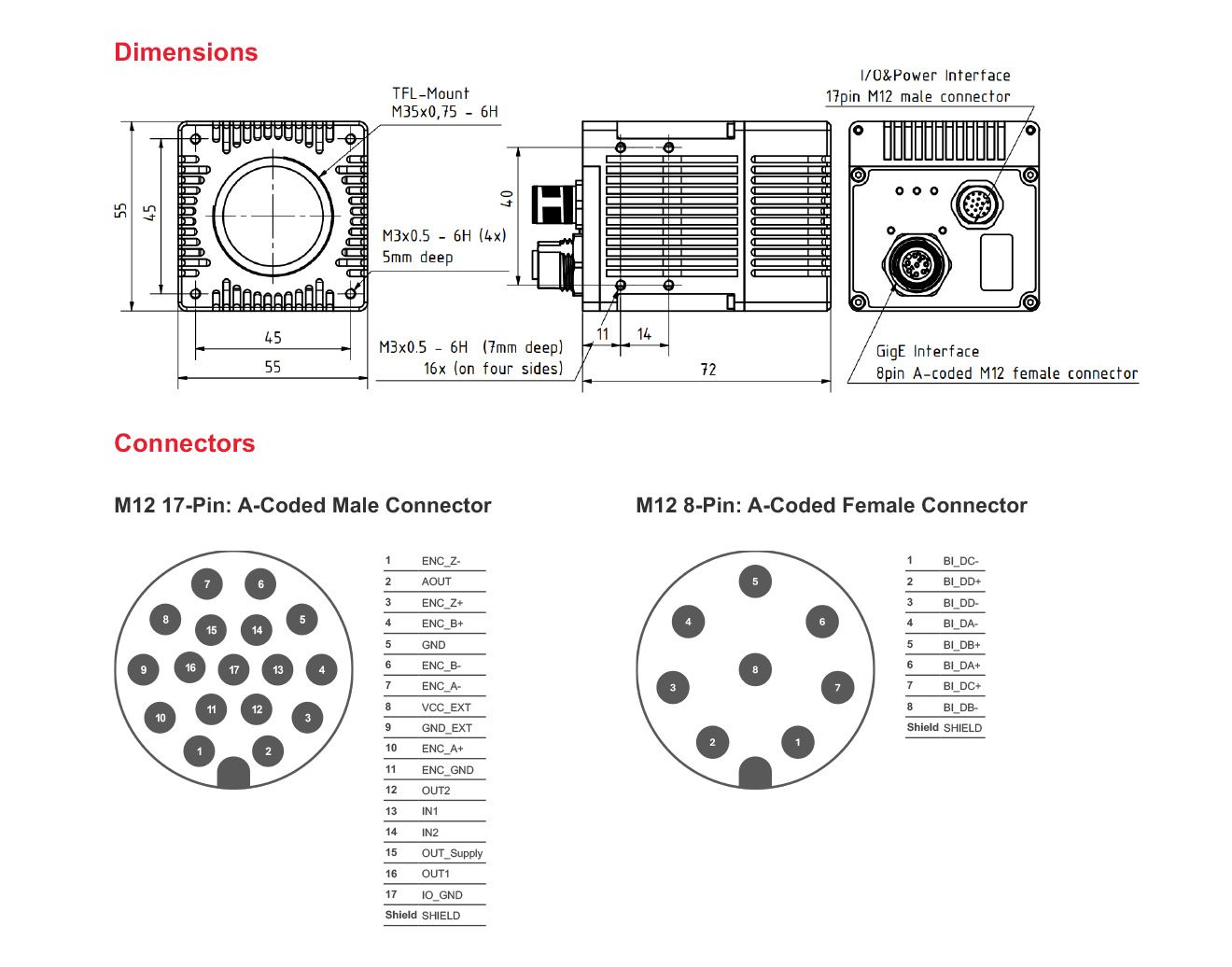

- High industrial protection class IP67 (with lens protection)

- Compatible with GenICam 3.0

Please log in or register to view prices or buy products.

High-resolution 3D camera for a wide range of industrial applications

As part of the new C6 series, AT has developed four different camera models with varying speeds and resolutions. Additionally, AT’s 3D camera features an expanded laser interface, allowing you to directly control your individual laser.

You are currently viewing a placeholder content from Vimeo. To access the actual content, click the button below. Please note that doing so will share data with third-party providers.

More Information