High-Performance Kick-Off 2025: AT starts the new year with NBASE-T & high-power laser

March 5, 2025

The latest technological developments, advanced product innovations and features requested by customers: at the end of January, the northern German technology company AT Sensors from Bad Oldesloe near Lübeck gave a comprehensive outlook for the year 2025 as part of a live webinar. In this high-performance kick-off, the six-strong team led by CTO André Kasper presented the advantages that customers can expect from AT in 2025 and the unique benefits that customers can look forward to in terms of 3D sensor technology. From improved camera models and powerful lasers to flexible configuration options – this year promises a variety of innovative solutions that will take efficiency and precision in industrial applications to a new level.

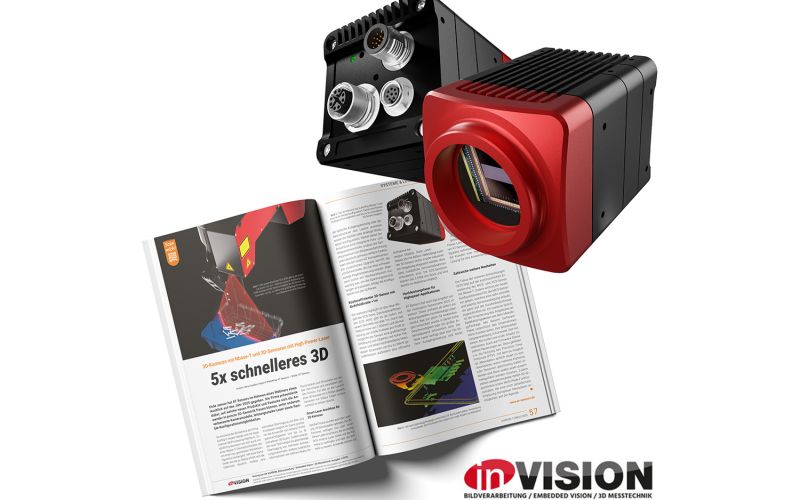

3D camera: New model with NBASE-T and increased data rate of up to 5 Gigabit

One of the most exciting product innovations concerns the new 3D camera models, as AT is starting the new year with three updates. Not only will the camera appear in a new design and with a new internal S8 processing platform, it will also be presented with a new data interface – NBASE-T. This interface is also accompanied by a redesigned connector configuration, which offers optimized connectivity and numerous enhanced functions. With the introduction of NBASE-T, the North German technology company is catapulting itself directly to the forefront of technical possibilities in 3D sensor technology. With a bandwidth of up to 5 gigabits per second, the data rate increases considerably, enabling faster transmission of image and profile data. Firstly, users benefit from significantly higher profile speeds and 3D scans that are up to five times faster, which makes a significant difference in high-speed applications, for example. Secondly, the new technology allows the simultaneous transmission of several evaluation features, so that additional information such as several peaks, reflection data and scattering data can be captured and processed at the same time. The launch of a 3D camera model with 2.5 Gigabit / s is initially planned for May, with variants with a data rate of 5 Gigabit / s expected to follow in the third quarter. The laser and I/O interfaces have also been optimized. The AT 3D cameras now have a smart laser connection, which enables external lasers to be connected directly to the camera and controlled via the software. Users can, for example, read out the current optical output power or the operating time of the laser and configure the digital or analog modulation. Furthermore, the new smart laser connection also offers integrated pulse and intensity control, so that the synchronization of image sensor exposure and laser pulse works just as easily as with an AT compact sensor. An additional upgrade concerns the I/O interface, which now allows software-based level adjustment. Whereas previously a hardware swap was necessary to adjust the voltage settings, this can now be conveniently configured via software. These improvements not only make the new 3D camera models more powerful, but also significantly more flexible for use in a wide range of applications and easier to integrate into existing systems.ECS series: New cost-efficient 3D sensor with more than 1 m field of view

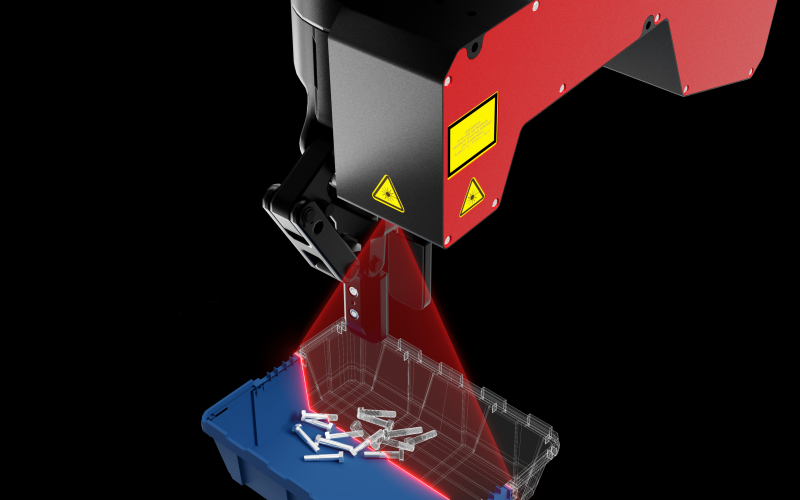

Another highlight is the new model in the ECS series, the cost-efficient AT sensor range. The ECS 4090 sensor is now available with a large field of view of over one meter, which is particularly beneficial for applications such as bin picking in robot guidance, for inspecting baked goods in the food industry and for checking parcels in logistics. Thanks to the field of view of 1020 mm and the high resolution of 4096 points per profile, the ECS sensor enables large-area detection of objects with high precision and delivers highly detailed measurement data. Fast scan rates of up to 24 kHz also ensure efficient recording of moving objects. Also worth mentioning is its laser class 2M with a wavelength of 660 nm. This means that the 3D sensor can be used safely in any industrial environment without the need for additional protective measures. Apart from its technical sophistication, the ECS series also impresses with its optimal price-performance ratio, which represents a cost-effective solution for numerous industries: The ECS sensors start at €5,550 each and are the company’s first product series to even be available in the webshop.MCS series: New high-performance laser for high-speed applications

In addition to the improvements in camera technology and in the lower sensor price segment, AT Sensors has also expanded the range of its modular sensor series, the MCS series. This now includes a powerful high-performance laser module, which has been developed primarily for applications where high speed or a large working distance is required. These include, for example, the measurement of road surfaces, the inspection of rails or extrusion processes with aluminum or steel slabs. The new laser has ten times the output power and therefore offers a maximum optical power of 2.5 watts. This enables precise 3D scans even in difficult lighting conditions such as bright ambient light, significantly expanding the range of applications for the sensors. This upgrade offers decisive advantages, particularly in areas where homogeneous illumination is important, such as the inspection of metal surfaces or large-area measurements. Another important feature is the ability to generate laser lines up to 2.8 meters wide, which is an advantage in intralogistics, for example. The new lasers are available in two wavelength variants, 760 nm and 808 nm, with further variants in the blue and infrared range being planned and are also due to be launched this year. The MCS High-Power Laser, just like the other sensors in AT’s modular sensor series, is customizable via the MCS configurator, providing customers with a tailored solution for their specific application. This high level of customization makes the MCS series a particularly attractive choice for companies that require flexible and powerful 3D sensor technology.Outlook for 2025: that’s not all by a long shot

In addition to the innovations already presented, CTO André Kasper gave an exciting outlook on further developments planned by AT Sensors for 2025, with a central focus on the continuous expansion of the MCS and XCS series with NBASE-T. There will also be a new configuration tool for the modular compact sensors (MCS), which will enable super-fast and precise sensor design tailored to customer requirements Another important step is the expansion of the range of application packages such as the AT MetrologyPackage. With this software package, the company helps its customers to implement their image processing application in the shortest possible time using a no-code/low-code approach. There are also significant innovations at firmware level, which will also benefit users with sensors already installed in the field. These include the use of the Precision Time Protocol (PTP), which makes it possible to synchronize measurement data precisely when several cameras or sensors record data at the same time and these need to be merged exactly later. The North German technology company’s development agenda also includes advanced WARP 3D algorithms and multi-peak functionalities that enable even more detailed recording of complex measurement data. These innovations underline AT Sensors’ clear goal of continuing to pioneer future-oriented developments in 3D image processing in order to offer customers forward-looking solutions at the highest technical level. Related Articles

Social